You’ve probably conducted countless visual inspections throughout your career. Walking the facility, checking panels, looking for obvious signs of wear or damage. It’s fundamental work, certainly, but there’s a significant limitation to what your eyes can actually detect. Thermal problems develop beneath surfaces, inside enclosures, and within energised equipment where visual inspection simply cannot reach safely. This is where thermal imaging technology steps in to change how you approach safety and maintenance work.

The technology itself has evolved considerably over the past decade. What once required bulky, expensive equipment now fits into handheld devices that provide immediate feedback during your inspections. Yet the real transformation isn’t about the hardware becoming more portable. It’s about gaining access to information that was previously invisible to you.

What IR-Fusion Technology Actually Does

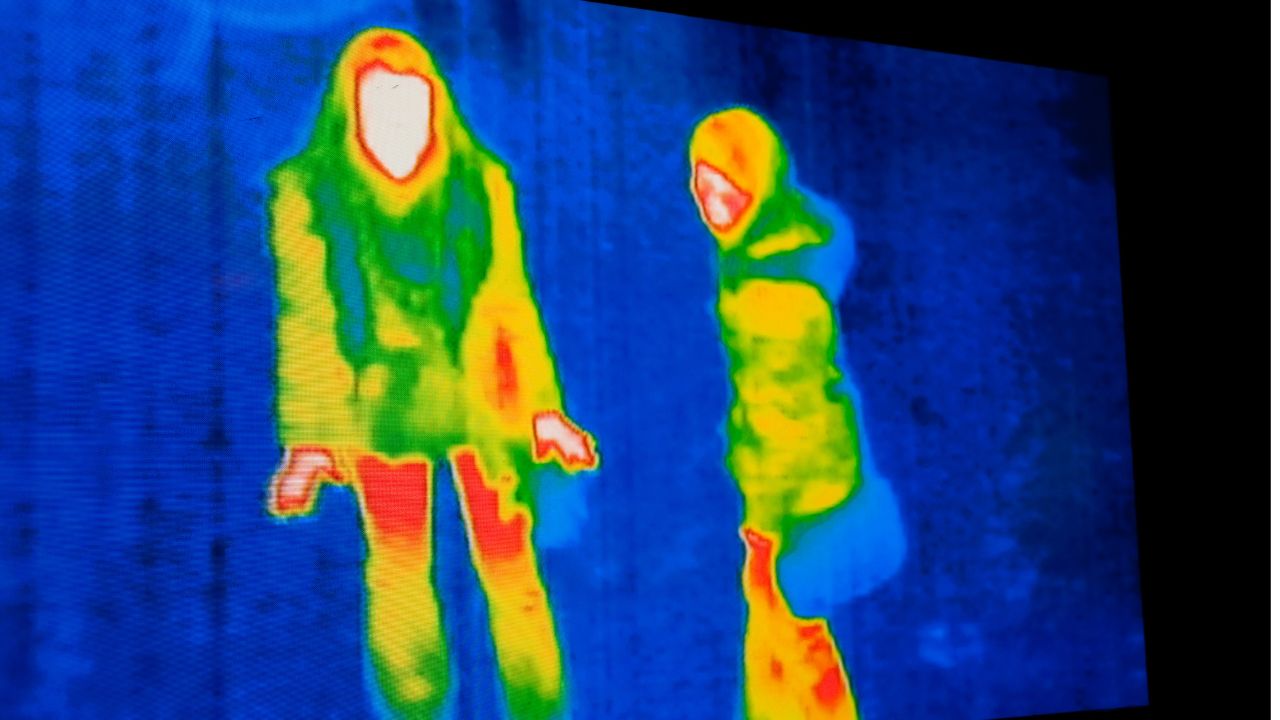

IR-Fusion Technology combines two distinct imaging capabilities into a single view. You’re seeing both the visible light image of what you’re inspecting and the infrared thermal signature simultaneously. The composite image overlays thermal data onto the familiar visual reference, which makes interpreting results considerably more straightforward than working with pure thermal imagery alone.

The physics behind it is relatively simple. Everything with a temperature above absolute zero emits infrared radiation. Hotter objects emit more of it. Your thermal camera detects this radiation and converts it into a visible temperature map. Different colours or brightness levels represent different temperatures, giving you a clear picture of thermal patterns across the surface you’re examining.

Why does this matter for your daily work? Because thermal patterns reveal problems that remain completely hidden during visual inspections. An electrical connection might look perfectly sound from the outside whilst running dangerously hot inside due to increased resistance. A bearing might appear fine whilst generating excess heat from inadequate lubrication or misalignment. These are the problems that escalate into failures, fires, and safety incidents when they go undetected. Thermal imaging gives you advance warning before the situation deteriorates.

The dual-view approach means you’re never questioning what you’re actually looking at. The visual component provides context whilst the thermal overlay shows you exactly where the temperature issues exist. This combination proves particularly valuable when you’re documenting findings for reports or explaining problems to colleagues who weren’t present during the inspection.

Electrical System Inspections and Fault Detection

Electrical faults generate heat. It’s one of the most reliable indicators that something has gone wrong or is heading in that direction. When you scan electrical panels, switchgear, and distribution equipment with thermal imaging, you’re essentially looking for temperature anomalies that signal problems developing within the system.

Loose connections are among the most common issues you’ll discover. The increased resistance at a poor connection point generates heat that’s immediately apparent in a thermal image. You might see one termination glowing hot whilst identical connections nearby remain cool. That temperature difference tells you exactly where attention is needed before the loose connection leads to arcing, equipment damage, or fire.

Overloaded circuits show distinct thermal signatures as well. The conductors and protective devices carry more current than they should, generating excess heat throughout the affected circuit. This becomes particularly valuable when you’re trying to identify the source of recurring trips or when load distribution has changed over time without corresponding electrical system updates.

Phase imbalances create thermal patterns you can spot immediately. When one phase carries significantly more load than the others, the imbalance appears as temperature differences across what should be thermally similar components. This matters because imbalances reduce efficiency, stress equipment, and can lead to premature failures.

The safety advantage here is substantial. You’re identifying these problems from a safe distance rather than requiring close physical contact with energised equipment. Traditional testing methods often involve invasive procedures that increase risk, but thermal scanning lets you assess conditions whilst maintaining appropriate clearances. Of course, thermal imaging complements rather than replaces other safety measures, and you should continue following established protocols including the use of insulated matting and other protective equipment during electrical work.

The range of use cases for IR-Fusion Technology in electrical systems extends well beyond basic fault detection. You can assess transformer loading and cooling system effectiveness, identify failing surge protective devices before they compromise your equipment, and verify that electrical installations are performing as designed. When integrated with your overall electrical testing programme, thermal imaging provides a non-invasive method for continuous condition monitoring between more detailed inspections.

Deteriorating insulation presents another thermal signature worth understanding. As insulation breaks down, you’ll often see increased surface temperatures where the insulation should be providing protection. This early warning lets you schedule repairs before the insulation fails completely and creates a fault condition.

Temperature thresholds matter when you’re evaluating what you find. A connection running 10°C above ambient might not concern you, but that same connection at 40°C or 50°C above ambient temperature indicates a problem requiring immediate attention. The specific thresholds depend on the equipment and operating conditions, which is why understanding your systems matters as much as having the thermal imaging equipment itself.

Preventive Maintenance Applications

Reactive maintenance is expensive. You’re responding to failures, dealing with unplanned downtime, and often paying premium prices for emergency repairs and expedited parts. Thermal imaging shifts your maintenance approach from reaction to prediction by revealing equipment condition whilst everything is still running.

The concept of thermal trending transforms how you make maintenance decisions. Rather than working from a fixed schedule or waiting for obvious problems, you’re comparing thermal images captured over weeks or months to track how conditions change. That motor that’s gradually running warmer? It’s telling you something about bearing condition, lubrication adequacy, or load characteristics. You can schedule maintenance during planned downtime rather than experiencing an unexpected failure during production.

Mechanical systems give you plenty of thermal information if you know what to look for. Motors, pumps, and gearboxes all have normal operating temperature ranges. Deviations from those ranges indicate developing problems. A bearing running hot suggests inadequate lubrication, misalignment, or wear. The friction generates heat that appears clearly in thermal images before vibration analysis or sound would detect the problem.

Belt drives and chain systems show thermal patterns related to tension and alignment. Excessive tension generates heat in bearings and drive components. Poor alignment creates uneven wear patterns that appear as localised hot spots. Catching these issues early prevents catastrophic failures and extends component life considerably.

HVAC systems benefit substantially from thermal inspection capabilities. You can identify blocked filters by the temperature differential across the filter housing. Failing compressors run hot before they fail completely. Heat exchangers show effectiveness through thermal patterns that reveal fouling, blockages, or degraded performance. Ductwork insulation problems become obvious when you’re looking at thermal images rather than trying to assess insulation integrity through visual inspection alone.

The financial case for predictive maintenance becomes clear when you compare the cost of scheduled repairs against emergency breakdowns. You’re buying parts at regular prices rather than paying premium freight charges. You’re planning the work during convenient times rather than pulling maintenance staff from other priorities. You’re avoiding the production losses that come with unexpected equipment failures.

Optimising your maintenance schedule means doing less unnecessary work whilst catching genuine problems earlier. Traditional time-based maintenance often involves inspecting or servicing equipment that’s functioning perfectly well. Condition-based approaches using thermal data let you extend intervals where appropriate and intervene promptly where thermal patterns indicate developing issues.

Building Diagnostics and Energy Efficiency

Buildings waste energy in ways that remain hidden during ordinary occupancy and operation. Air leaks, insulation deficiencies, and thermal bridges all increase heating and cooling costs without creating obvious visible symptoms. Thermal imaging makes these energy losses apparent by showing you the temperature differentials that indicate problems.

Insulation performance varies considerably even within the same building. Installation quality, settling over time, moisture intrusion, and gaps around services all degrade the insulation’s effectiveness. A thermal survey reveals exactly where your building envelope is failing. You might discover that certain wall sections show dramatically different thermal characteristics compared to adjacent areas, indicating missing or damaged insulation that’s been hidden behind finished surfaces for years.

Windows and doors often create significant thermal losses. Failed seals allow air infiltration that appears as distinct thermal patterns around frames and sashes. Double-glazed units that have lost their seal show different thermal characteristics compared to properly functioning windows nearby. This information lets you prioritise window replacement or sealing efforts based on actual thermal performance rather than age or appearance.

Roof inspections using thermal imaging identify moisture intrusion before interior damage becomes apparent. Wet insulation has different thermal properties than dry insulation, creating patterns that show you exactly where water has penetrated the roof membrane. Finding these problems early prevents structural damage and interior water damage whilst the repairs remain relatively straightforward.

Air leakage deserves particular attention because it accounts for substantial energy losses in most buildings. Thermal imaging conducted during appropriate temperature differentials between inside and outside reveals air movement paths around building penetrations, at material junctions, and through building envelope defects. The visual evidence of these leaks supports remediation efforts and demonstrates the value of air sealing investments.

Thermal bridging occurs where conductive materials create paths for heat flow through the building envelope. Structural elements, window frames, and service penetrations can all act as thermal bridges that significantly reduce overall insulation effectiveness. Identifying these bridges helps you understand your building’s actual thermal performance rather than relying solely on design specifications that may not account for as-built conditions.

Seasonal considerations affect when certain building diagnostics work best. You need adequate temperature difference between inside and outside to generate clear thermal patterns. Surveys conducted during mild weather often fail to show problems that become obvious during extreme temperatures. Planning your thermal surveys for cold winter nights or hot summer days provides the most useful data about building performance.

The business case for building improvements becomes much clearer when you can quantify energy losses with thermal data. Rather than making generalised assumptions about potential savings, you’re showing specific areas where energy is escaping and providing evidence for calculating actual return on investment for remediation work.

Industrial Safety Monitoring

Safety in industrial environments extends well beyond electrical systems and building conditions. Process monitoring applications rely heavily on temperature control, and thermal imaging gives you real-time visibility into whether processes are operating within safe parameters.

Chemical processes often involve exothermic reactions or heat transfer operations where temperature control is critical. You can monitor reactor walls, heat exchangers, and process equipment from safe distances using thermal imaging. Temperature deviations from normal patterns alert you to potential problems before they escalate into dangerous situations. This remote monitoring capability keeps your staff away from hazardous areas whilst maintaining oversight of critical operations.

High-temperature operations including furnaces, kilns, and industrial ovens all benefit from thermal monitoring. Refractory degradation shows up as hot spots on exterior surfaces where insulation has failed. Burner performance issues create temperature patterns that indicate problems with fuel delivery or combustion air. Finding these issues before complete failures occur prevents production interruptions and maintains safe operating conditions.

Fire prevention capabilities deserve serious consideration. Materials that are approaching their ignition temperature create thermal signatures that give you advance warning. Storage areas, waste handling systems, and production processes all present fire risks that thermal imaging can help you monitor. Regular thermal surveys of areas where combustible materials accumulate might just prevent a fire before it starts.

Your safety systems themselves need verification. Fire suppression equipment, emergency cooling systems, and other protective measures should be functioning properly when needed. Thermal imaging helps you verify that these systems are ready to perform their intended functions. Checking that fire pump motors aren’t overheating or that sprinkler system components show normal thermal patterns provides confidence in your protection systems.

Comprehensive approaches to worker safety integrate multiple technologies and practices, with thermal imaging serving as one valuable tool among many. The remote monitoring capabilities particularly benefit situations where direct access would expose workers to excessive heat, radiation, or chemical hazards.

Hazardous environments where explosive atmospheres, toxic materials, or extreme conditions exist can often be monitored using thermal imaging from safe locations. This reduces the frequency of entries into dangerous areas whilst maintaining surveillance of equipment condition and process parameters.

Documentation from thermal imaging supports incident investigation when problems do occur. The thermal images captured during routine monitoring provide baseline information about normal operating conditions. If an incident occurs, you can review thermal data from the period leading up to the event to understand what changed and potentially why the incident happened.

Documentation and Compliance Benefits

Thermal images create objective records that supplement your inspection reports and maintenance documentation. You’re not relying solely on written descriptions or subjective assessments. The thermal image shows exactly what conditions existed at the time of inspection, providing evidence that’s difficult to dispute.

Insurance requirements increasingly include condition monitoring and preventive maintenance programmes. Demonstrating that you’re actively monitoring equipment and facility conditions using thermal imaging may influence your premiums. More importantly, it provides evidence of due diligence should you ever need to make a claim related to equipment failure or facility damage.

Regulatory compliance varies by industry and jurisdiction, but electrical safety regulations generally require periodic inspection and testing of electrical systems. Thermal imaging surveys provide documentation that you’re maintaining awareness of system conditions and addressing problems before they create unsafe situations. The reports generated from thermal inspections supplement other compliance documentation and demonstrate systematic attention to safety obligations.

Internal quality systems benefit from standardised thermal inspection protocols. When you establish regular thermal inspection routes and document findings consistently, you’re creating a comprehensive record of facility conditions over time. This historical data becomes invaluable for understanding equipment life cycles, planning capital improvements, and justifying maintenance budgets.

Maintenance budget discussions often involve competing priorities and limited resources. Thermal images provide compelling visual evidence of problems that require investment. Showing leadership a thermal image of an overheating electrical connection or failing equipment component is far more effective than abstract descriptions. The visual impact helps secure necessary funding for repairs and improvements.

Record-keeping practices should include systematic organisation of thermal images and reports. Creating libraries organised by equipment, location, and date lets you track long-term trends and quickly retrieve historical data when needed. The software that accompanies thermal imaging equipment typically includes database functionality for managing inspection records, though you might integrate this data into your existing computerised maintenance management system for centralised access.

Long-term condition trending reveals patterns that inform strategic decisions about equipment replacement, facility upgrades, and resource allocation. You might discover that certain equipment types consistently develop thermal issues whilst others prove more reliable. This information influences purchasing decisions and helps you focus preventive maintenance efforts where they deliver the most value.

Making the Investment Work for You

Implementing thermal imaging within your safety and maintenance programmes requires thoughtful consideration of how the technology fits your specific needs. The question of equipment ownership versus contractor services depends largely on inspection frequency and internal capabilities.

Purchasing your own thermal imaging equipment makes sense when you’re conducting inspections frequently enough to justify the capital investment and when you have staff willing to develop the necessary expertise. The equipment pays for itself relatively quickly if you’re currently hiring contractors for work you could perform internally. Modern thermal cameras designed for industrial maintenance applications have become considerably more affordable whilst offering excellent performance.

Using contractors remains appropriate when your inspection needs are occasional or when the applications require specialised expertise beyond what your staff can reasonably develop. Electrical utilities, building envelope specialists, and industrial maintenance contractors who focus on thermal imaging bring experience that comes from conducting hundreds or thousands of inspections. They often spot subtle patterns and potential issues that less experienced users might miss.

A hybrid approach works well for many organisations. You maintain basic thermal imaging capabilities for routine inspections and ongoing monitoring whilst engaging specialists for comprehensive surveys or particularly complex applications. This gives you the benefits of regular internal surveillance combined with periodic expert assessment.

Training deserves emphasis because thermal imaging is emphatically not simply point-and-shoot technology. Understanding how to interpret thermal images correctly requires knowledge of the systems you’re inspecting, the factors that influence thermal patterns, and the limitations of the technology itself. Emissivity variations, reflective surfaces, environmental conditions, and equipment operating states all affect what you see in thermal images. Misinterpreting these factors leads to false positives that waste resources or, worse, missing genuine problems because you didn’t recognise the thermal signature.

Professional certification programmes exist for thermographers, and investing in training for your staff pays dividends in inspection quality and confidence. Even basic training significantly improves your ability to use thermal imaging effectively and avoid common pitfalls that compromise inspection results.

Building thermal imaging into regular inspection routines rather than treating it as a special procedure improves consistency and ensures the technology gets used. Including thermal scans in standard electrical inspection checklists, preventive maintenance rounds, and building surveys makes the technology part of your normal workflow rather than something that requires special planning and approval.

Realistic expectations matter. Thermal imaging cannot see through walls or inside closed enclosures. It detects surface temperatures and infers internal conditions based on how those temperatures relate to normal operating patterns. You’re not getting x-ray vision, but rather a powerful tool for detecting thermal anomalies that indicate potential problems.

Integration with other inspection methods creates the most comprehensive condition assessment. Ultrasonic testing, vibration analysis, oil sampling, and traditional visual inspections all provide different information about equipment condition. Thermal imaging complements these methods rather than replacing them. The most effective maintenance programmes combine multiple technologies to build a complete picture of system health.

Building internal expertise versus relying entirely on external specialists involves balancing development costs against long-term capabilities. Starting with contractor support whilst training your staff lets you transition gradually toward internal capability. External specialists can provide periodic audits of your internal inspection programme to ensure quality and help identify areas where additional training or equipment might benefit your operations.

Thermal imaging enhances your safety and maintenance programmes by providing information that wasn’t previously accessible. It’s a tool that reveals hidden problems, supports predictive maintenance strategies, and helps you make better decisions about resource allocation. The technology continues to evolve, becoming more capable and accessible, but the fundamental value remains unchanged. You’re gaining visibility into thermal conditions that directly impact safety, reliability, and operational efficiency. That visibility transforms how you approach inspection work and maintenance planning across your entire facility.